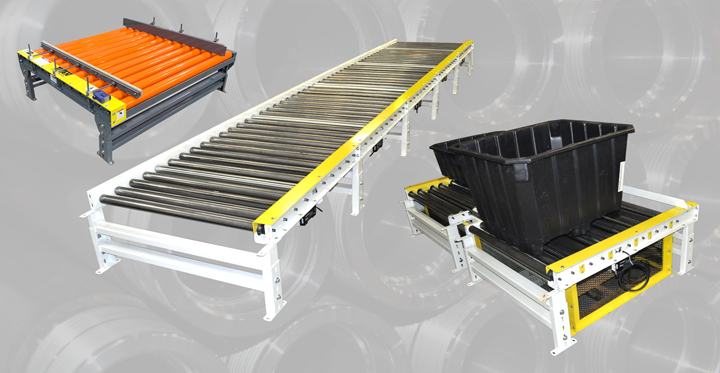

Motorized Driven Roller Conveyors (MDR)

Motorized Driven Rollers (MDR) are conveyor rollers with their own internal motors. Each motor roller controls a small zone of free-turning rollers. This inherently modular design makes designing and building a Zero Pressure Accumulation Conveyor systems faster and easier than conventional conveyor system. MDR conveyor systems are also easier to change and expand as your business needs change.

Only running when necessary, Motorized rollers may result in as much as 70% energy savings over line shaft, air operated, or chain driven conveyor. Lower maintenance costs due to reduced wear and tear is also a big return on investment comparable to conventional methods.

Motorized Driven Roller (MDR) technology is also safer than conventional conveyor. 24V Motor Roller are much quieter, and because individual rollers are low voltage, and lower torque, your warehouse staff are less likely to encounter accidental injury.

The advantages of the Motorized Driven Roller Conveyor are:

- Modular design improves layout/easy to reconfigure

- Run on demand/less noise, wear, and energy

- Non-contact zero pressure/product protection

- Compact low profile/multi-level usage

- Reversible/less hardware required

- No scheduled maintenance/lower operating cost

- Improves working environment (quieter, safer, better ergonomics and cleaner operation)

- Lower power consumption

- Low voltage/safety and lower cost

- Simple installation/lower cost

- Soft start and stop/low G-forces

- Simplifies conveyor operations

- Improves material flow

- Variable speed/versatility to suit each requirement

- Choice of control level to meet needs and budget