Industry Solutions

Contact us here to learn more.

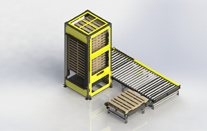

Pallet Handling Solutions

Titan Conveyors™ manufactures a full line of standard Pallet Conveyors and accessories to handle every size, type, and weight of pallet. Even though 40” x 48” pallets with weights up to several thousand pounds are most common, our recent applications included moving 10,000 pound concrete bunkers and 8,000 pound steel coils.

Learn More

Stamping Industry Solutions

For over 30 years, Titan Conveyors™ has provided a complete line of heavy duty conveyors to move material in stamping operations. Whether you are handling work in process, finished parts, or scrap; there is a Titan conveyor to handle any piece from the size of a dime to the size of a car.

Learn More

Assembly Line Solutions

More than ever, manufacturers and system integrators are turning to Titan Conveyors™ for our unique ability to provide exactly what is needed to make production line employees safe and efficient. Titan ConveyorsTM has the products and experience to provide innovative assembly line conveyor systems, from basic assembly to complex

Learn More

Cooling - Drying Solutions

When hot parts need cooling or wet parts need drying, you need an experienced partner. Titan Conveyors™ can provide a solution. Typical applications are in foundry and forge operations where components at several thousand degrees Fahrenheit need to be conveyed carefully as they cool.

Learn More

Quenching Solutions

Titan’s Quench Conveyor is designed to quench or cool heavy-duty parts, cool die cast parts and scrap. It’s built with a liquid tight horizontal tank. It can be supplied with wire mesh belt, plastic or steel belt. Choose from a complete line of liquid-tight conveyors for your die cast, heat transfer, parts cooling or coating operation.

Learn More

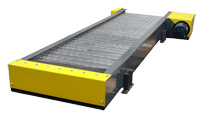

Chip & Machine Tool Solutions

Titan was founded in 1981 on the premise that we could make a superior hinged steel belt conveyor for moving chips out of metalworking operations. A key Titan advantage is our exclusive tight tolerance Radial Sidewing which alleviates the most common frustrations with traditional scrap chip conveyors.

Learn More

Ammunition Manufacturing Solutions

Titan Conveyors™ is a premier manufacturer & supplier of conveyors to every major manufacturer of ammunition in the United States, Titan has developed a line of specialized plastic belt, rubber belt, and steel belt conveyors for the careful handling of parts from lead projectiles to plastic wads to brass cups.

Learn More

Parts Handling Solutions

Titan Conveyors™ has a conveyor solution for moving and elevating all types of parts including small delicate parts, bulky awkward parts, and heavy metal parts. Typical industries include injection molding, candy making, fastener manufacturing, stamping, and die casting.

Learn More

Candle Manufacturing Solutions

Titan Conveyors™ is a leading supplier of conveyors to the Candle Making Industry. Commonly used are standard or customized versions of Titan’s Model 124, wire mesh conveyor. We offer special features unique to the industry such as extremely slow moving belts for cooling and pitched drip collection pans for mounting underneath conveyors.

Learn More

Pulp & Paper Industry Solutions

Titan Conveyors™ is a premier manufacturer of conveyors for handling paper bailing, virgin bale handling and roll handling for the paper industry. We manufacture our conveyors with years of maintenance free reliabilty for operation in the most hostile environments.

Learn More

Stainless-Galvanized Conveyor Solutions

Titan Conveyors™ are generally available in optional Stainless Steel or Galvanized construction. The reasons for using special materials vary widely from aesthetics to chloride resistance to wash down. The degree to which equipment is made out of these materials is strictly based on the application

Learn More