Forging Industry Conveyors

A forging operation can be brutal on equipment. Titan ConveyorsTM, with our focus on heavy duty industrial conveyors and a wide range of models, can provide solutions throughout your forging operations. We listen carefully to the demands of the application, so your conveyor is designed from the start to hold up to the task. Something as simple as understanding exactly how the product is loaded onto the conveyor can make the difference in whether the conveyor lasts one year or twenty years.

Challenge and Solution

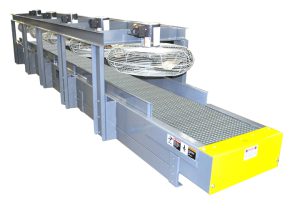

A new heat treating line was installed at a forge making parts for the heavy equipment industry. At the exit of the furnace the parts had to free fall more than six feet and then be cooled. With parts weighting up to fifty pounds, and a discharge span of five feet, a special conveyor was required that was wide enough and could handle the impact. Titan offered the Model 660 six inch pitch Hinged Steel Belt Conveyor with impact plates on the belt surface to handle the impact and disperse the heat. The drive was designed to move the belt at a crawl, allowing the parts to have time to cool.

Typical Conveyor Used in the Forging Industry:

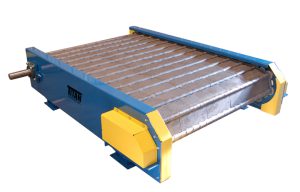

- Hinged steel belt conveyors for transporting and elevating metal products, including hot product

- Mesh belt conveyors for transporting pieces at their very highest temperature

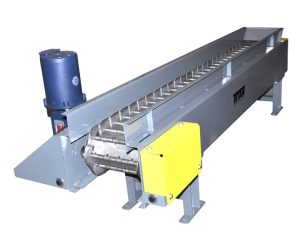

- Chain conveyor for moving individual pieces over long distances, both while hot or after cooling

- Heavy duty chain driven live roller conveyor, heavy duty multi strand chain conveyor, chain transfers, and turntables for moving bins of work in process

- Heavy duty chain driven live roller conveyor and multi strand chain conveyor for moving pallets of finished product

- Cooling-Drying Conveyors in foundry and forge operations where components at several thousand degrees Fahrenheit need to be conveyed carefully as they cool.