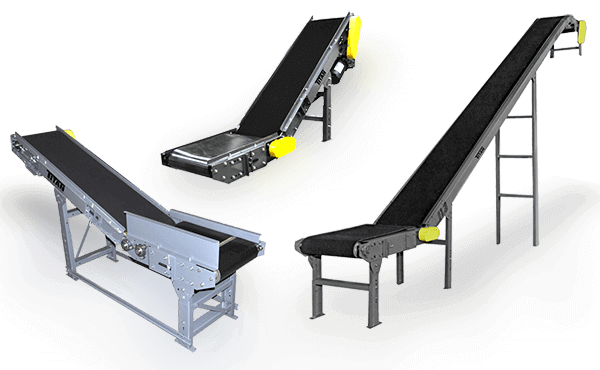

Floor to Floor / Incline Conveyors Maximize Efficiency

Titan’s inclined, floor-to-floor conveyors allow you to maximize your floor space and make elevation changes efficiently.

What are Floor to Floor Conveyors?

Floor to floor conveyors, also known as incline conveyors, are material handling systems designed to efficiently transport products between different elevations. They excel at maximizing your floor space by utilizing inclines to move items from one level to another.

Key benefits of floor to floor conveyors:

- Increased Efficiency: By moving products vertically, you can optimize your facility layout and streamline production processes.

- Space Saving: Floor to floor conveyors eliminate the need for ramps or additional floor space for elevation changes.

- Versatility: Titan offers a wide range of floor to floor conveyor options to suit various capacities, inclines, and product types.

Floor to Floor Conveyor Applications:

Incline conveyors are ideal for a variety of applications, including:

- Assembly lines

- Packaging lines

- Warehouses

- Distribution centers

- Manufacturing facilities

Titan Incline Conveyor Options:

Incline Conveyor Model 204

The Model 204 is a light-duty floor-to-floor unit designed for lighter loads and shorter lengths. The 4″ diameter drive pulley will handle numerous products on the incline belt with an end drive or optional center drive and take-up for reversing applications.

Incline Conveyor Model 208

When you need to handle heavier loads or require wide product handling, the Model 208 should be your choice. The 8″ diameter drive pulley gives you the versatility to convey heavier loads over longer distances.

Both units can be supplied with optional side rails, center drive and take-ups, power feeders and floor supports or ceiling hanger brackets.

Call Titan Industries toll-free at 800-558-3616 for more information or individual model specifications.